These properties make the welding of cu and cu alloys difficult as compared to welding of carbon steels.

Electromagnetic impact welding of aluminum to stainless steel sheets.

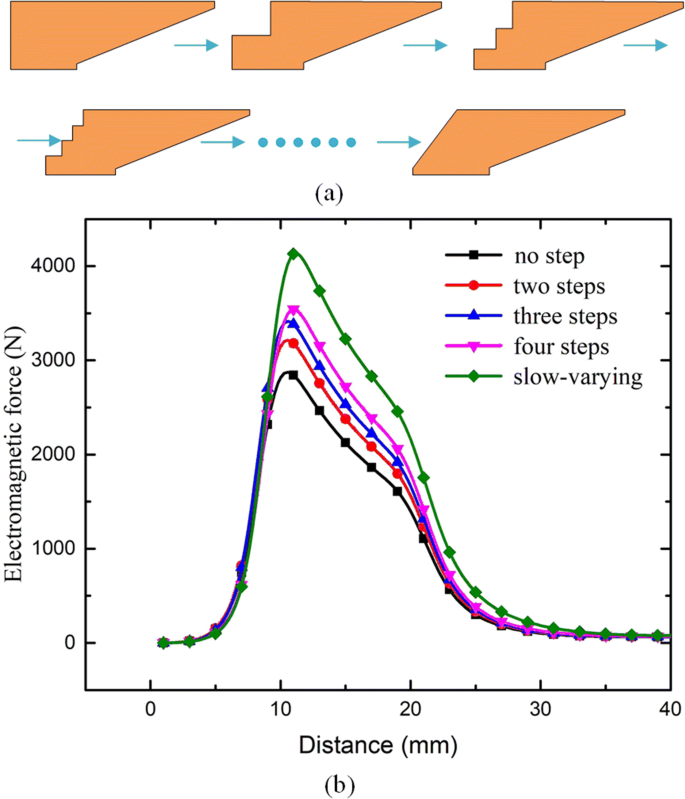

The magnetic field shaper that is placed between the metal components and an electromagnetic coil is used to concentrate the magnetic field around the weld zone and then enhance the generated lorentz force acting on the metal.

Stainless steel sheet of 0 25 mm thickness can be accelerated with the use of the aluminum driver sheet and welded to 1 mm thick aluminum sheet by electromagnetic impact welding at capacitor discharge energy of 4 09 kj.

Kulkarni electromagnetic impact welding of aluminum.

2014 developed an electromagnetic weld pool support system for high power.

A study has been carried out to characterize the electromagnetic impact welding of 0 5 mm thick cu sheets.

The objective of this work is to propose a magnetic pulse spot welding mpsw process with the aid of a field shaper for achieving the connecting of metal components.

Joining of dissimilar metal combinations like copper to stainless steel cu to ss is however a challenging task owing.

To stainless steel sheets j.

The present study investigates the feasibility of electromagnetic impact welding of cu to cu sheets by using al as the driver sheet.

The welding cu to ss is accomplished by using al drivers to.

Microstructure of the al to ss electromagnetically impact welded sheet shows continuous weld.

The welding cu to ss is accomplished by using al drivers to accelerate cu and ss work sheets.

13 shows the microstructural cracks of two welding specimens an aluminum alloy sheet and a galvanized steel sheet an aluminum alloy sheet and an ungalvanized steel sheet.

The application of electromagnetic em impact technique is demonstrated for welding copper cu to stainless steel ss sheets.

2008 made similar kind of observations when they successfully joined 1 mm al sheet with 0 25 mm stainless steel ss sheets using an aluminium plate as a driver for ss sheet.

Tensile shear strength of stainless steel aluminum sheets mpw joints.

The application of electromagnetic em impact technique is demonstrated for welding copper cu to stainless steel ss sheets.

2008 reported the electromagnetic impact welding of aluminum to stainless steel sheets.