Some of the common sheet metal design guidelines included are minimum distance between holes cutouts slots distance between holes cutouts slots to part edge and bends multiple bends in same direction minimum bend radius minimum radius.

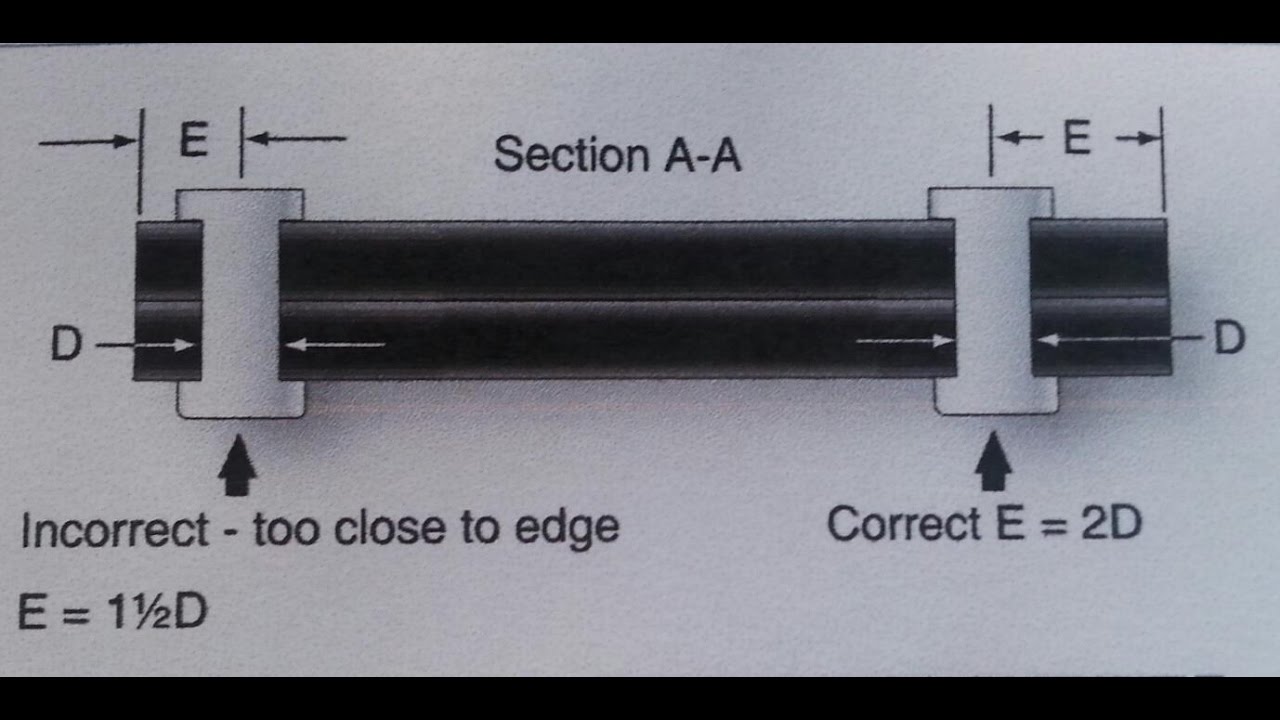

Edge distance for holes in sheet metal.

Avoid large sheet metal parts with small bent flanges.

A 1 degree tolerance on all bend angles.

Bends in sheet metal are manufactured using sheet metal brakes.

In most cases minimum hole bend distance equals 1 5 times sheet thickness plus bend radius though the multiplying factor may increase as hole size increases in diameter.

Though these calculations can help you approximate the minimum distance you ll need to place between a hole and the edge or bend in sheet metal different situations call for.

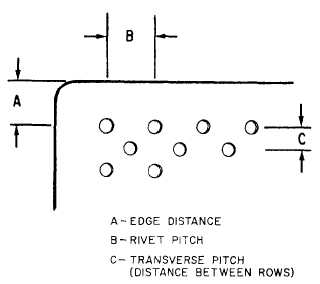

On most repairs the general practice is to use the same rivet spacing and edge distance that the manufacturer used in the surrounding area or the structural repair manual for the particular aircraft may be consulted figure and edge distance.

The minimum distance the edge of a hole should be from a form is three times the material thickness plus the bend radius.

The minimum space between the edge and holes should be at least the sheet.

Dfmpro provides pre configured design guidelines dfm best practices which helps to develop better quality parts at reduced cost.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

The strength of riveted met.

In a sheet metal design specifying hole sizes locations and their alignment is critical.

Creating an extruded hole using a punching process requires extreme pressure force.

45 gussets shouldn t be designed to be more than 4 times material thickness on their flat edge.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Therefore the minimum distance between the extruded hole to edge if maintained.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger.

Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.

For holes the distance between the gusset and the hole s edge should be at least 8 times material thickness.

Dfmpro for sheet metal.

Extruded holes very close to the part edge can lead to sheet metal deformation or tearing.